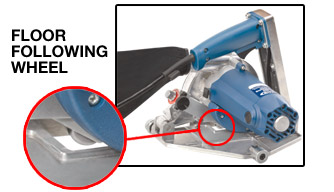

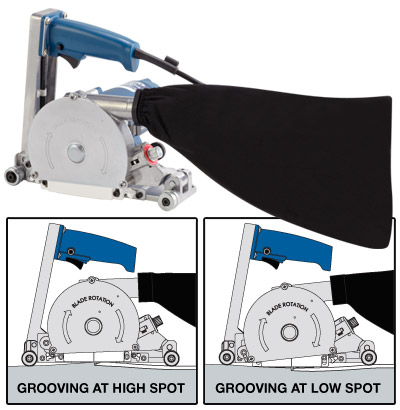

No. 968 Floor Following Groover

This tool tracks in the seamline to cut a trapezoidal groove for welding. It maintains consistent grooving depth even when floors are not level, up to 1/8″ of variation over one foot of seamline. The floor following wheel rides on the floor to raise or lower the blade in response to variation. A spring-loaded floor following dust shroud improves dust control. Includes a 12 tooth 130mm carbide-tipped blade (No. 971), and carrying case. Diamond grit blade for metal-impregnated safety floors is sold separately (No. 972). 110VAC 9A No load RPM 12,000. Max. groove depth 3.5mm. Net weight: 20.5 lbs.