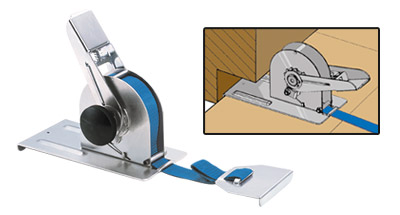

No. 565 18′ Strap Clamp

This clamp pulls planks together across lengths of up to 18 feet. The nylon strap coils internally as the strap is retracted and stays out of the way. The long base hooks onto planks even under toe spaces. Includes large knob for rapid retraction after clamping is complete. Designed for wood installers and a real time saver! Net weight: 2.2 lbs.